Molybdenum Saafi ah Silig buufiyo kulaylka loogu talagalay xameetida iyo iska caabin ah

Nooca iyo Cabirka

Zhaolixin Tungtsen & Molybdenum waxay ku siin karaan silig molybdenum iyadoo loo eegayo sawiradaada iyo baahidaada.

| Dhexroorka (μm) | Miisaanka (mg/200mm) | Miisaanka (mg/200mg) Dulqaadka (%) | Dulqaadka Dhexroorka (%) | ||

| Fasalka 1 | Fasalka 2 | Fasalka 1 | Fasalka 2 | ||

| 20≤d <30 | 0.65 ~ 1.47 | ±2.5 | ±3 | ||

| 30≤d <40 | >1.47~2.61 | ±2.0 | ±3 | ||

| 40≤d<100 | >2.61-16.33 | ±1.5 | ±3 | ||

| 100≤d<400 | >16.33~256.2 | ±1.5 | ±4 | ||

| 400≤d<600 | ±1.5 | ±2.5 | |||

| 600≤d<3200 | ±1.0 | ±2.0 | |||

Astaamaha

| Guryaha | Metric | Imperial |

| Xoogga xajinta | 324 MPa | 47000 psi |

| Xoog xiirid (heerka cadaadiska torsional 0.25/s) | 500 MPa | 72500 psi |

| Xoogga wax-soo-saarka cadaadiska (0.01% dhalidda) | 400 MPa | 58000 psi |

| Hababka bartinimada | 330 GPA | 47900 ksi |

| Qaabka dabacsanaanta heerkulka sare (@2000°C/3630°F) | 160 GPA | 23200 ksi |

| Kordhinta kulaylka: | 5 x 10-6 cm/cm @ 25 oC | |

| Waxqabadka Korontada: | 34% IACS | |

| Habdhaqanka Kulaylka: | 1.38 W/cm/K @ 298.2 K | |

| Iska caabin Koronto: | 5.2 microhm-cm @ 0 oC | |

Mo-wire waa madow caadi ah oo lagu daboolay garaafka.Ka dib markii graphite la saaro waa dhalaal macdan ah.

Codsiyada

- Mashiinka goynta siliga

- Si loo soo saaro qaybaha isha iftiinka korontada iyo qaybaha faaruqinta korontada

- Si loo soo saaro walxaha kuleylka iyo qaybaha refractory ee foornooyinka heerkulka sare

- Ku buufinta jeexjeexa iyo jeexjeexyada qaybaha baabuurta iyo mishiinnada kale si kor loogu qaado daalkooda

- La2O3 ama Y2O3 doped Refractory Mo-wire ayaa diyaar ah

Farsamada

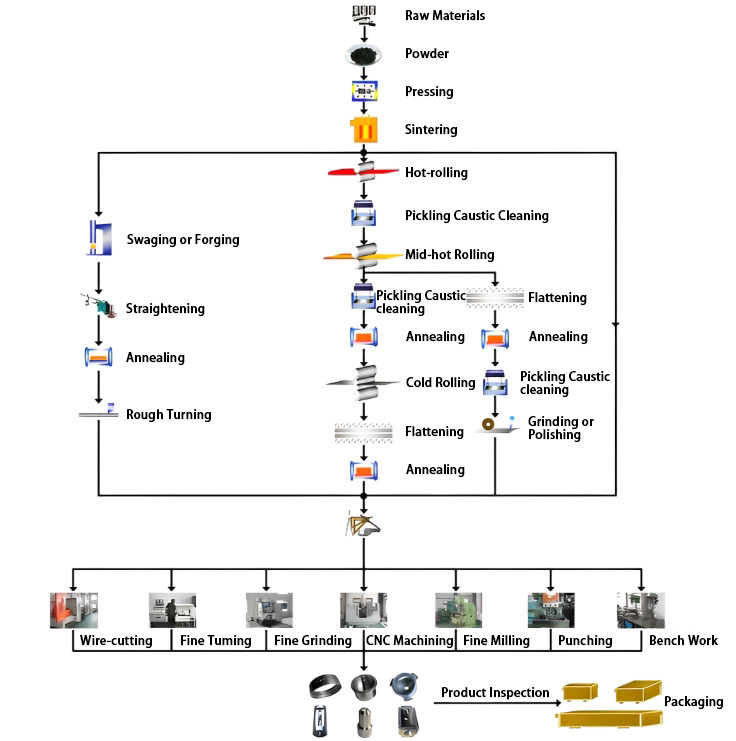

Walxaha ceeriin:Laga bilaabo alaabta ceeriin, waxaan dooranaa alaabta ceeriin oo tayo sare leh, taas oo aad u caan ah xasiloonida iyo joogtaynta alaabta.Aqoonso noocyada kala duwan ee alaabta ceeriin oo calaamadee lambarka dufcada.Qayb kasta oo alaabta ceeriin ah waa in la muunadeeyaa, la baaraa oo la kaydiyaa.Hubi raadinta badeecad kasta oo dhammaatay oo si joogto ah u wanaaji tayada alaabta.

Budada:Xakamaynta habka wax-shiidka ee alaabooyinka birta ee Zhaolinxin waa mid aad u sax ah, oo leh dhowr isku-dar ah oo waaweyn iyo goobo gariir si loo hubiyo in alaabta ku jirta habka firirka iyo isku-dhafka si buuxda loo walaaqo oo si siman loo qaybiyo, si loo hubiyo in isku-dhafka ururka gudaha alaabta.

riixaya:Inta lagu jiro habka isku-dhafka budada, budada waxaa lagu cadaadiyaa qalabka cadaadiska isostatic si ay u sameeyaan qaab-dhismeedkeeda gudaha mid la mid ah oo cufan.Zhaolixin waxay leedahay caaryar dufc ah oo aad u fiican, sidoo kale waxay leedahay qalab cadaadis ah oo isostatic ah si ay ula kulmaan wax soo saarka dufcadaha aadka u weyn ee alaabada.

Isku-duubnidaIn birta budada ah, ka dib markii budada birta ay sameeyaan cadaadis isostatic, waxaa lagu kululeeyaa heerkul ka hooseeya barta dhalaalka ee qaybaha ugu muhiimsan si ay u sameeyaan qaybo isku xira, si loo hagaajiyo waxqabadka alaabta, taas oo loo yaqaan sintering.Ka dib marka budada la sameeyo, jidhka cufan ee laga helo sintering waa nooc ka mid ah walxaha polycrystalline.Hannaanka qallafsantu wuxuu si toos ah u saameeyaa cabbirka hadhuudhka, cabbirka daloolka iyo qaabka xadka hadhuudhka iyo qaybinta qaab-dhismeed yar, kaas oo ah habka ugu muhiimsan ee biraha budada ah.

Been abuurasho:Habka been-abuurka ah wuxuu ka dhigi karaa maaddadu inay hesho cufnaan sare, sifooyin farsamo oo wanaagsan, waxayna door ka ciyaaraan xoojinta dusha sare.Xakamaynta saxda ah ee heerka habaynta iyo heerkulka been abuurka ee tungsten iyo maaddooyinka molybdenum waa arrin muhiim u ah waxqabadka sare ee Zhaolixin tungsten iyo walxaha molybdenum.Habka farsamaynta ee isticmaalka mishiinka been abuurka ah si cadaadis loogu saaro birta banaan si balaastik ahaan u qalloocin si loo helo been abuur leh sifooyin farsamo oo gaar ah, qaab iyo cabbir gaar ah.

Wareegid:Geedi socodka duubista ayaa ka dhigaysa walxaha birta ah inay soo saaraan balaastig joogto ah oo hoos yimaada cadaadiska duubista wareega, oo ay helaan qaabka qaybta loo baahan yahay iyo sifooyinka.Iyada oo leh tignoolajiyada horumarsan ee tungsten iyo molybdenum qabow iyo tikniyoolajiyad wareeg ah oo kulul iyo qalab, laga bilaabo tungsten iyo birta molybdenum bannaan ilaa soosaarka tungsten iyo foil molybdenum, Zhaolixin waxay kuu dammaanad qaadaysaa tignoolajiyada wax soo saarka ee horumarsan iyo sifooyinka birta sare.

Ku-Daawaynta Kulaylka:Ka dib habka foornada iyo duubista, maaddada ayaa la hoos geeyaa habka daaweynta kulaylka si gebi ahaanba loo baabi'iyo culeyska qaabdhismeedka gudaha ee maaddada, sii ciyaarista wax-qabadka maaddada, oo ay u sahlanaato mashiinnada xiga.Zhaolixin waxay leedahay daraasiin foornooyin faaruq ah iyo foornooyinka hydrogen daaweynta kulaylka si ay u buuxiso gudbinta degdega ah ee amarrada wax soo saarka tirada badan.

MashiinkaMaaddada Zhaolixin ayaa lagu sameeyay daaweyn kulayl oo dhammaystiran, ka dibna waxaa lagu farsameeyay cabbirro kala duwan oo loo habeeyay iyadoo la adeegsanayo qalabaynta qalabka sida leexinta, shiididda, jarista, shiididda, iwm. iyo dalool la'aan, kaas oo dabooli kara baahida macaamiisha.

Xaqiijinta Tayada:Kormeerka tayada iyo xakamaynta ayaa laga samayn doonaa alaabta ceeriin iyo tallaabo kasta oo wax soo saarka , si si joogto ah loo hubiyo tayada alaabta kasta.Isla mar ahaantaana, marka alaabta la dhammeeyo laga keeno bakhaarka, muuqaalka, xajmiga iyo abaabulka gudaha ee alaabta ayaa mid mid loo tijaabiyaa.Sidaa darteed, xasilloonida iyo joogtaynta alaabooyinka ayaa si gaar ah caan u ah.